The vacuum oven is an essential tool used in laboratories and industrial settings for drying, curing, and heat treatment processes under reduced pressure conditions. This topic holds great importance due to its wide range of applications in various fields such as materials science, pharmaceuticals, and electronics. The vacuum oven allows for the gentle and controlled removal of moisture or volatile substances from sensitive samples without subjecting them to high temperatures or oxidative conditions.

By discussing the vacuum oven, we gain insights into its principles, functionalities, and advancements, which contribute to improved product quality, stability, and manufacturing efficiency. Exploring the topic of the vacuum oven is crucial for researchers, engineers, and manufacturers seeking reliable and precise methods for low-temperature drying and processing of sensitive materials.

What’s a vacuum oven for?

Vacuum oven applications

Objects treated with vacuum ovens

Vacuum oven, hi-temp oven and microwave dryer comparison

Setting-up and installing a vacuum oven

What’s a vacuum oven for?

A vacuum oven, or vacuum drying oven, is primarily used to expedite the drying process by employing vacuum and heat. As the pressure decreases, the boiling point of the solvent also decreases, allowing the vacuum oven to remove moisture and volatile substances at lower temperatures. Furthermore, since air is removed from the vacuum oven, heat transfer inside becomes more efficient. By reducing the levels of oxygen (O2) and moisture, the drying efficiency is enhanced while the risks of oxidation and explosion are mitigated. Some vacuum ovens can even be equipped with inert gases like nitrogen (N2) or helium (He) to prevent oxidation, corrosion, or scaling.

The advantages of a vacuum oven can be summarized as follows:

-

Reduction of solvent boiling point, enabling lower heating temperatures. This makes it suitable for processing heat-sensitive and volatile substances.

-

Minimization of oxidation, making it suitable for handling flammable and explosive substances.

-

Increased drying efficiency through improved heat transfer and the removal of oxygen and moisture.

Vacuum oven applications

The most common vacuum oven applications include:

-

Moisture Removal:

One of the primary functions of vacuum ovens is to remove moisture from equipment or pharmaceutical products, particularly when dealing with fragile or temperature-sensitive items like microchips and pharmaceuticals. Porous objects, in particular, tend to retain moisture within their pores, leading to potential product damage and failure. Vacuum ovens can effectively and gently eliminate moisture, thus preventing such product failures. -

Off-Gassing / Outgassing:

Sealants and lubricants used in certain metal components can often release moisture or chemical vapors. These residues have the potential to cause product or electronic component failure. Vacuum ovens play a crucial role in removing moisture and chemical residues through a process known as off-gassing or outgassing, as referred to in ASTM E595 standards for outgassing in a vacuum environment. -

Prevent Oxidation:

By controlling the temperature and vacuum level, vacuum ovens can effectively prevent oxidation, corrosion, or scaling. This feature is particularly important in the pharmaceutical industry, where oxidation can compromise product quality. -

Bake-Out & Degassing:

Bake-out involves increasing the temperature inside the vacuum oven to force volatile chemicals out of the objects being treated. Since the oxidization reaction is effectively controlled within the vacuum oven, these chemicals can be removed more safely and efficiently. Bake-out is also utilized for degassing, as heated liquids release gases in the form of bubbles, which can then be captured and removed by the vacuum system.

Due to the aforementioned reasons, vacuum ovens find wide application in various industries, including electronics, semiconductor, aerospace, and pharmaceuticals. Additionally, the ability to dry objects at lower temperatures makes vacuum ovens valuable in the food industry, where high temperatures may lead to nutrient loss or food deterioration. For further information on drying methods, please refer to CNS 5033 “Methods for the Examination of Moisture in Food.”

Objects treated with vacuum ovens

Vacuum ovens are suitable for treating the following objects due to their ability to dry at lower temperatures:

-

Heat-sensitive substances: This includes fruits and vegetables, enzymes, microorganisms, antibiotics, and other sensitive materials that may degrade or lose their efficacy at higher temperatures.

-

Objects that are difficult to dry: Vacuum ovens are effective in drying powdery or granular substances that may clump together or form lumps when subjected to traditional drying methods.

-

Flammable or explosive substances: While caution must be exercised when dealing with flammable or explosive substances, vacuum ovens can be used for their drying. However, it is crucial to choose a vacuum oven that is certified as explosion-proof, such as those compliant with ATEX, IECEx, or Hazloc standards, to ensure safety during the drying process.

Vacuum oven, hi-temp oven and microwave dryer comparison

A high-temperature oven operates by heating objects under normal pressure. Fans are commonly utilized to circulate hot air throughout the chamber, facilitating the drying process.

In contrast, a microwave dryer differs from a vacuum oven primarily in its heating principle. It employs microwave radiation to generate heat energy within a vacuum environment. While the scope of applications may overlap with vacuum drying, the appropriate drying method should be chosen based on the specific characteristics of the sample.

|

Drying device |

Vacuum oven |

Hi-temp oven |

Microwave dryer |

|

Heat generation |

Heat convection/Heat radiation |

Heat convection |

Microwave radiation |

|

Heating principle |

Vacuum lowers liquid boiling point and accelerate evaporation |

Heat with fan circulation |

Vacuum lowers liquid boiling point and accelerate evaporation |

|

Heating temperature |

Low |

High |

Low |

|

Heating efficiency |

High |

Lower |

Very high |

|

Appropriate for substances |

Heat sensitive substances Easily-oxidized substances Difficult-to-dry substances Flammable/explosive substances Light-weighted substances |

General substances |

Heat sensitive substances Easily oxidized samples Decomposable samples Light weight sample |

|

Applications |

Chemistry, biology, medicine, precision materials, food, aerospace |

Food, agriculture, environment |

Food (mainly), chemistry, biology, medicine |

Setting-up and installing a vacuum oven

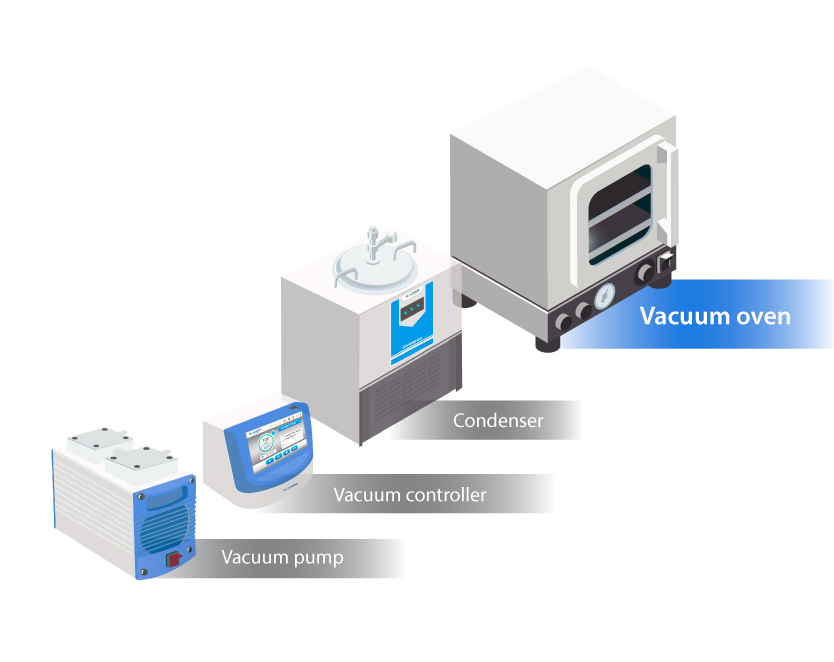

Vacuum ovens are generally equipped with a vacuum pump to achieve the required vacuum in its chamber, as well as several other devices depending on the applications.

- Vacuum controller

Controlling the vacuum more accurately and stably is crucial in order to prevent oxidation and deterioration of the target object. Vacuum controllers with a linear control function can gradually reduce the pressure, thereby avoiding sudden changes in airflow within the chamber. This feature is particularly important when drying powders or lightweight objects like feathers. - Condenser

The condensing device is installed between the vacuum oven and the pump (or controller). As the oven is primarily used for drying, the evaporated gases often consist of a significant amount of water or solvent vapor. The condensing device plays a crucial role in efficiently recovering the vapor and preventing harmful gases from escaping into the environment. Additionally, it serves to prevent vapor and hot gas from entering the pumps or controllers. - Vacuum pump

Choose the pump flow rate based on the vapor volume; it is usually suggested to be twice as high as the volume of the oven. If the objects to be dried are heat-sensitive or contain liquid with a higher boiling point, it is recommended to use pumps that can create a higher or deeper vacuum. When considering user safety and the lifespan of the equipment, select chemical-resistant pumps if the objects being dried contain corrosive substances, such as lithium batteries. A quick guide to pump selection is provided below.

|

|

Oven volume |

Suggested pump model |

Air flow (L/min) |

Max. vacuum (mbar) |

|

|

General objects |

< 15 L |

DC Chem 610 Pro |

37 |

7 |

|

|

Rocker 410 |

23 |

25 |

|

||

|

< 30 L |

Rocker 911 |

65 |

25 |

|

|

|

< 60 L |

Rocker 901 |

120 |

85 |

|

|

|

Tanker 150 |

142 |

1.3 x 10-1 |

|

||

|

Tanker 230 |

85 |

6.6 x 10-2 |

|

||

|

Chemicals (solvents, acids) |

< 15 L |

DC Chem 610 Pro |

37 |

7 |

|

|

Chemker 410 / 411 |

20 |

10 |

|

||

|

Chemker 610 / 611 |

34 |

7 |

|

||

|

Rocker 910C |

37 |

15 |

|

||

|

< 30 L |

Chemker 600 |

65 |

65 |

|

|

|

Rocker 900C |

60 |

99 |

|

References:

- A Comparison of the Volatile-Solvent Method with the Vacuum-Oven Method for Determining Moisture Content of Cheese, Journal of Dairy Science, 1928

- Chapter 23 – Combined Microwave Vacuum Drying, Emerging Technologies for Food Processing, 2015

- Ultimate Guide to a Laboratory Vacuum Ovens, Lab Pro

- Vacuum Drying Ovens, DigiVac

- What is the difference between vacuum oven and drying oven?, NetDry