Peristaltic Pump, The Ultimate Tool for Liquid Distribution in Laboratories!

What is a Peristaltic Pump?

Peristaltic Pump Operation

Advantages and Features of Peristaltic Pumps

Factors Affecting Peristaltic Pump Performance

How to Maintain a Peristaltic Pump?

How to Select the Appropriate Peristaltic Pump Tubing??

Laboratory Peristaltic Pumps Applications

What is a Peristaltic Pump?

A lab peristaltic pump, also known as a roller pump, is a type of positive displacement pump. It is commonly used in laboratories for precise measurement and transfer of liquids.

The main advantage of a peristaltic pump is that only the peristaltic tubing comes into contact with the liquid, eliminating the risk of contamination. This makes it particularly important in sterile, precise control and cross-contamination prevention applications, such as medical, pharmaceutical, cell biology, and microbiology laboratories.

Peristaltic Pump Operation

The operating principle involves a motor driving rollers that compress the peristaltic pump tubing. This creates a vacuum, drawing in the liquid.

As the rollers rotate, the liquid is pushed out, effectively transporting the fluid. The tight fit between the tubing and rollers ensures that there is no backflow or siphoning when the pump stops.

Advantages and Features of Peristaltic Pumps

-

- Accurate Dosing: Precisely control the flow rate, ensuring consistent liquid delivery, suitable for high-accuracy scientific experiments and biotech processes.

- Quantitative Dosing: The pump parameters can be set to accurately measure the volume of liquid transported, achieving precise quantitative distribution.

- Flow Regulation: The flow rate of the liquid can be adjusted to meet different experimental conditions.

- Dry Running Capability: The pump can operate without liquid, making it durable in various experimental environments.

- Self-Priming: Peristaltic pumps can automatically draw in liquid without additional priming devices.

- Interchangeable Pump Heads: Users can replace the pump head as needed to accommodate different types and sizes of tubing, enhancing flexibility.

- Wide Range of Fluid Compatibility: A Peristaltic pump can handle various types of fluids, including corrosive, abrasive, viscous, and shear-sensitive liquids.

- No Contamination Risk: Only the tubing contacts the liquid, reducing the risk of contamination.

- Easy Maintenance and Low Cost: The tubing is easy to replace and clean, and the simple design results in lower maintenance costs.

- Reversible Operation: The pump head can rotate in both directions, allowing bidirectional fluid flow.

- No Slip: Ensures precise and stable fluid transfer without slippage.

All Advantages in One –

Buller 600 ( Buller 600 – DSP ) Dispensing Peristaltic Pump!

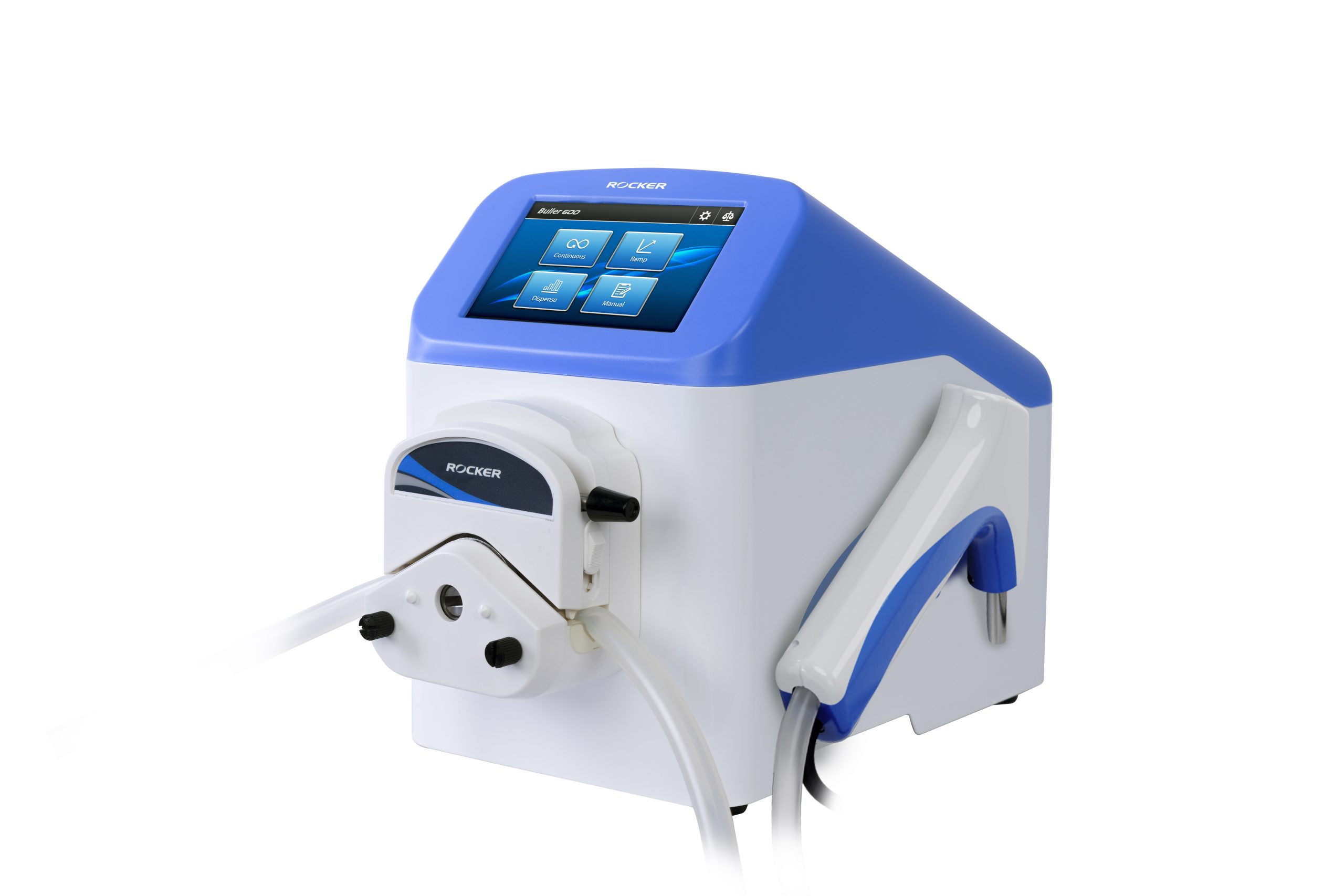

Rocker Buller 600 (Buller 600 – DSP)

- Built-in microbiological dispensing mode

- DSP equipped with a handheld dispenser, ergonomically designed for easy grip

- Features a reverse suction function to reduce dispensing errors

Buller 600 (Buller 600 – DSP) is designed for microbiological experiments and has passed multiple international certifications, making it an effective assistant for liquid dispensing in microbiological and biomedical laboratories!

Factors Affecting Pump Performance

The performance of a peristaltic pump in liquid distribution (flow rate) can be affected by the following factors:

- Speed: Higher speed increases flow rate.

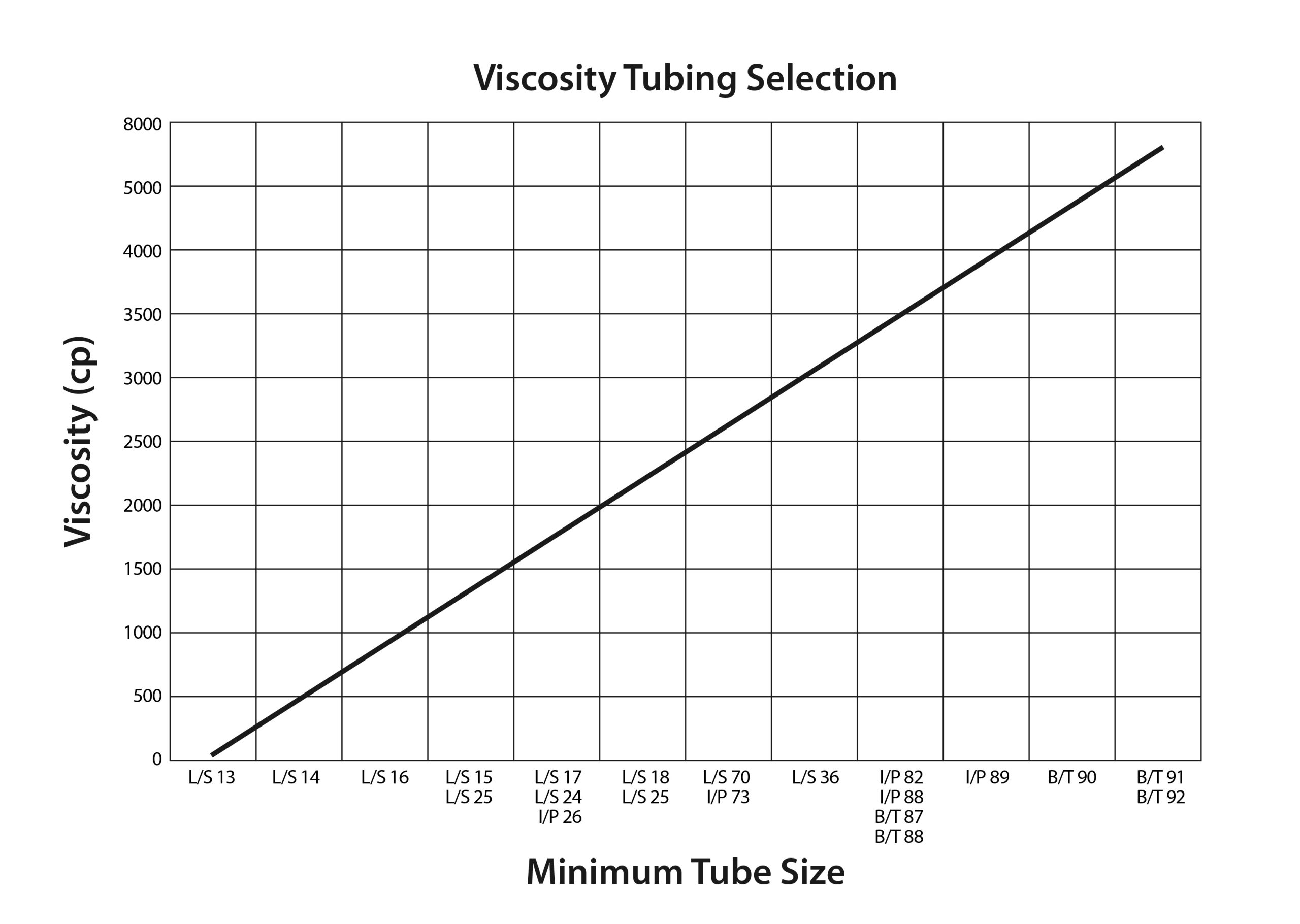

- Viscosity: Lower viscosity results in higher flow rate.

- Number of Rollers: Fewer rollers increase flow rate but more rollers reduce pulsation and ensure stable operation.

- Tubing Inner Diameter: Larger inner diameter increases flow rate but decreases dosing accuracy.

How to Maintain a Peristaltic Pump?

Peristaltic pumps are simple in structure, with no valves or seals, and the only maintenance part is the tubing.

After use, the tubing can be easily removed and cleaned by opening the pump head, saving time and maintenance costs.

Regularly replace the tubing based on the manufacturer’s recommendations, as continuous compression and friction can cause aging, deformation, and loss of elasticity.

How to Select the Appropriate Peristaltic Pump Tubing?

The choice of tubing material is crucial as the fluid comes into direct contact with it.

Common materials include PVC, silicone rubber, fluoroelastomer (e.g., FKM, FFKM), thermoplastic elastomer (TPE, e.g., PharMed), and thermoplastic vulcanizates (TPV).

Factors to Consider When Choosing Peristaltic Pump Tubing Material:

- Chemical Compatibility: Select tubing based on the chemical properties of the fluid.

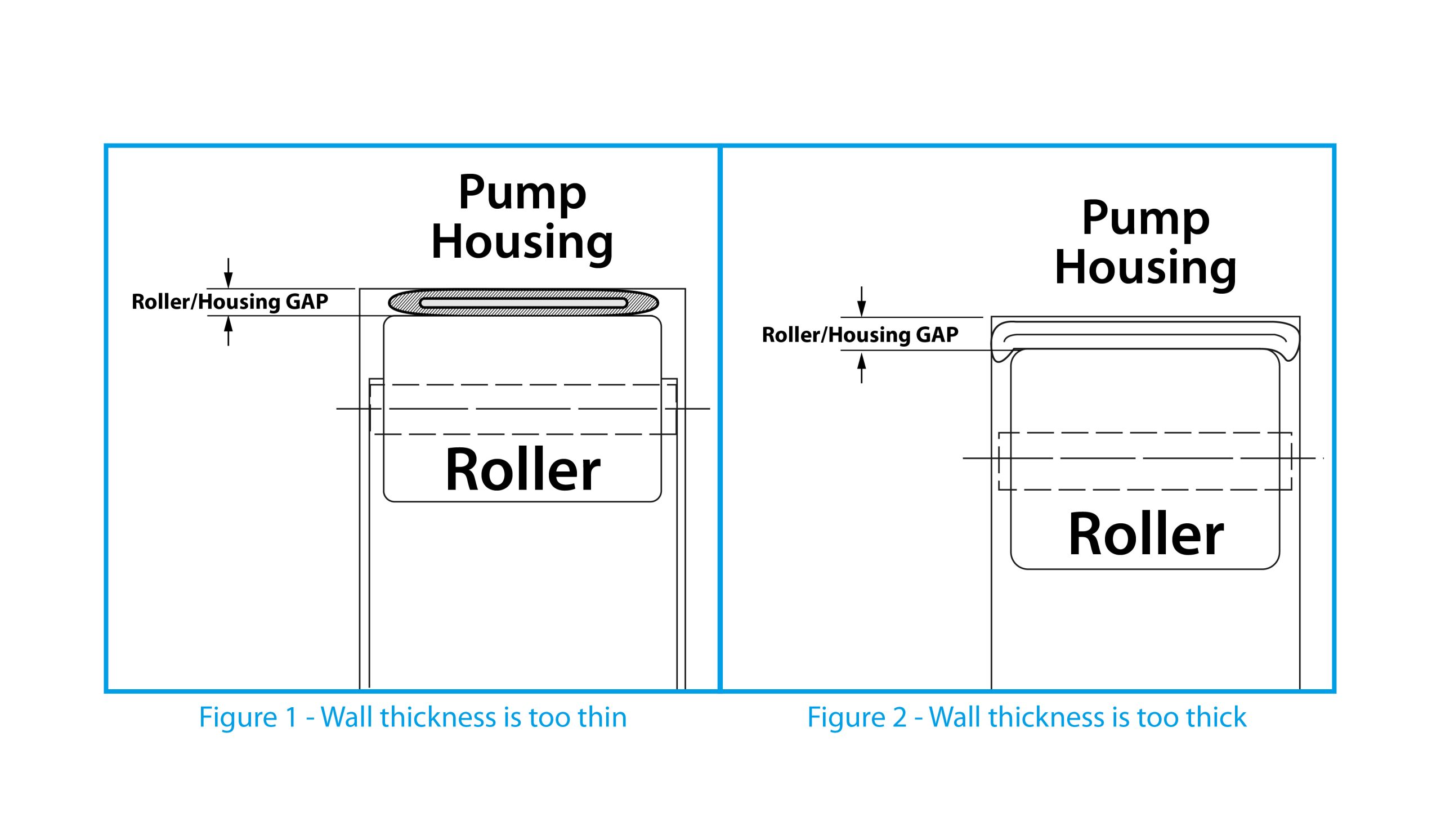

- Tubing Size: Select the appropriate peristaltic pump tubing diameter based on the desired flow rate. Flow rate is directly proportional to the inner diameter of the tubing but inversely proportional to dispensing accuracy. For more viscous liquids, it is recommended to use tubing with a larger inner diameter. Additionally, the outer diameter (thickness) of the tubing affects the fit between the tubing and the rollers. If the outer diameter is too thin, resulting in a poor fit, the peristaltic pump will not operate effectively; if it is too thick, it will cause excessive wear on the tubing and shorten the pump’s lifespan. Choose the suitable peristaltic pump tubing diameter according to the recommendations of the peristaltic pump manufacturer.

- Tubing Hardness: The hardness of the tubing affects the pump’s load and lifespan. Ensure the tubing can withstand the fluid’s backpressure.

- Sterile and Aseptic Operations: If there is a need for dispensing sterile or high-purity liquids, it is advisable to select peristaltic tubing that can withstand autoclaving. This type of material is suitable for handling sterile solutions, disinfectant solutions, and other liquids, such as culture media and buffer solutions in microbiology, as well as infusions and dialysis applications in the medical field.

Laboratory Peristaltic Pumps Applications

Peristaltic pumps can distribute a wide range of fluids, including sterile solutions, abrasive fluids, corrosive fluids, shear-sensitive fluids, and viscous fluids.

▲ Buller 600 features a built-in program specifically designed for microbial distribution, making it especially suitable for water quality microbiology, food microbiology, and pre-processing tasks such as E. coli testing.

Peristaltic Pumps Applications:

- Microbiology Labs: Distribution of culture media, buffers, diluents, and various sterile solutions.

- Medical and Biotech: Infusion, dialysis, extracorporeal circulation, and high-purity liquid analysis.

- Pharmaceutical and Food Processing: Precise control of drug, beverage, and food ingredient flow.

- Fermentation Food: Adding starter cultures to food ingredients at a consistent rate.

- Chemical and Environmental Engineering: Transporting corrosive liquids and wastewater treatment.

- Laboratory Reagent Distribution: Precise reagent and buffer distribution.

- Industrial Applications: Ink distribution in printing, dye transport in textiles.

- Aquarium Industry: Calcium reactor operations.

Reference