Total Suspended Solids (TSS) test is a crucial parameter in environmental monitoring and water quality assessment. This topic holds significant importance due to the impact of total suspended solids in wastewater, drinking water sources, and industrial processes.

TSS refers to the measurement of solid particles, both organic and inorganic, that remain in suspension in water or wastewater after gravity settling. Monitoring TSS levels helps evaluate the overall water quality, assess pollution levels, and detect the presence of harmful substances or sediments. By discussing TSS, we gain insights into its significance in environmental management, regulatory compliance, and the protection of human and ecological health.

Therefore, exploring the topic of Total Suspended Solids test is essential for environmental scientists, regulators, and policymakers seeking to maintain and improve water quality and ecosystem integrity.

Suspended solids and other solid substances in wastewater

What is total suspended solids?

Difference between suspended solids and turbidity

Total suspended solids (TSS) calculation

How to measure total suspended solids in water? Example of EPA Method 160.2

Membrane & pore size used in different countries

Suspended solids in wastewater

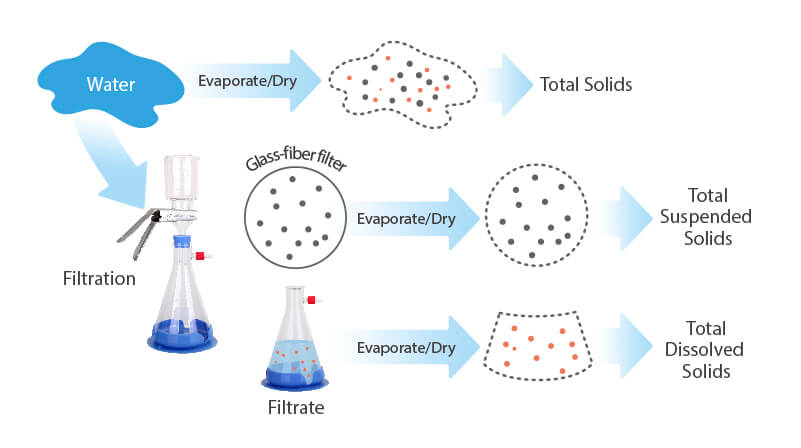

All natural waters contain solid substances, which can be classified as suspended solids and dissolved solids. Collectively, these substances are referred to as total solids (TS).

Total solids represent the residual matter left behind after the evaporation of water without any filtration. If the water sample undergoes filtration, the dried residues on the membrane filter are referred to as total suspended solids (TSS), while the particles obtained from the evaporated filtrate are called total dissolved solids (TDS).

What is total suspended solids?

Suspended solids generally refer to organic or inorganic particles that are visible when suspended in water. As the concentration of suspended solids increases in water, it leads to higher water turbidity and decreased photosynthesis. This, in turn, can result in low oxygen levels and the death of aquatic organisms. Industrial wastewater is one of the main sources of pollution in surface water due to its large volume and complex pollutants. The concentration of suspended solids in industrial wastewater can easily reach up to 30,000 mg/L.

Therefore, total suspended solids are an important parameter for analyzing wastewater quality and can serve as an indicator to determine the degree of pollution.

Difference between total suspended solids and turbidity

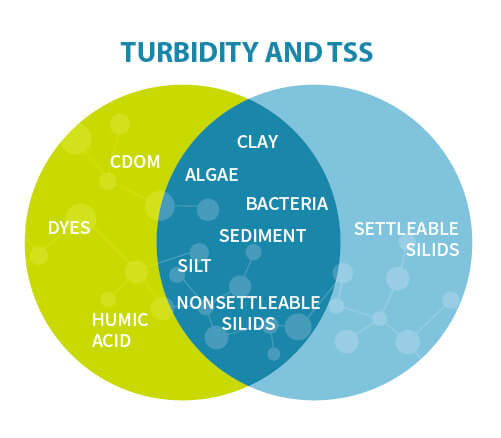

Turbidity refers to the extent to which light is scattered when it passes through water, and it can be observed as a measure of transparency or clarity. Various sources contribute to turbidity, including suspended solids, particles, fine organic matter, algae, plankton, or microorganisms. Low water transparency indicates high turbidity, which can affect the photosynthesis of aquatic plants and the growth of aquatic organisms. Additionally, high turbidity can disrupt disinfection processes and reduce the effectiveness of water purification. Turbidity is commonly measured using a nephelometer based on the principle of light scattering, and the unit of measurement is Nephelometric Turbidity Unit (NTU).

While both turbidity and total suspended solids measure the transparency of water, there are slight differences between these two methods of measurement. Turbidity is typically measured directly on-site using a portable device, providing immediate data. On the other hand, total suspended solids analysis in the laboratory using experimental techniques such as filtration and drying. Therefore, turbidity measures the degree of light scattering in a water body, whereas total suspended solids analysis provide a quantitative measure of fine particles, such as suspended solids, present in a water body. The particles that contribute to turbidity and total suspended solids differ, as illustrated in the following figure:

How to measure total suspended solids in water?

Example of EPA Method 160.2

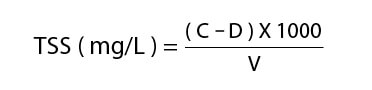

Gravimetric analysis is the most widely used method for measuring total suspended solids in water. It is a quantitative technique that involves weighing the residues collected on glass-fiber or cellulose ester membrane filters after filtration.

- This method can be applied to various types of water, including drinking water, surface water, saline water, as well as domestic and industrial wastewater.

- The practical range for determining total suspended solids using this method is from 4 mg/L to 20,000 mg/L.

Sample Handling and Preservation

If it is determined that the presence of non-representative particulates, such as leaves, sticks, fish, or lumps of fecal matter, is undesirable in the final result, they should be excluded from the sample.

Preserving the sample is not practical, and therefore, analysis should commence as soon as possible. It is recommended to refrigerate or place the sample on ice at 4°C to minimize microbiological decomposition of solids.

ROCKER MultiVac 310 – MS – A Filtration System

For large number of samples.

Save time & space.

Magnetic filter holders are included.MultiVac 310-MS-A Filtration System

Preparation of glass fiber filter disc

- Place the glass fiber filter on the membrane filter apparatus or insert it into the bottom of a suitable Gooch crucible with the wrinkled surface facing up.

- Apply vacuum while washing the disc with three successive 20 mL volumes of distilled water.

- Continue applying vacuum even after the water has passed through to remove all traces of water.

- Remove the filter from the membrane filter apparatus or both the crucible and filter if a Gooch crucible is used. Dry it in an oven at 103-105°C for one hour.

- Transfer the dried filter to a desiccator and store it until needed. Repeat the drying cycle until a constant weight is obtained (weight loss is less than 0.5 mg). Weigh the filter immediately before use.

- When handling the filter or crucible/filter, use forceps or tongs only.

Selection of Sample Volume

For a filter with a diameter of 4.7 cm, filter 100 mL of the sample. If the weight of the captured residue is less than 1.0 mg, the sample volume must be increased to ensure that at least 1.0 mg of residue is obtained.

If different filter diameters are used, begin with a sample volume equivalent to 7 mL per square centimeter of filter area. Collect a weight of residue that is proportional to the 1.0 mg mentioned above, ensuring an adequate amount is obtained.

Process of filtration

-

- Assemble the filtering apparatus and initiate suction.

- Wet the filter with a small volume of distilled water to ensure it is properly seated against the fritted support.

- Vigorously shake the sample and quantitatively transfer the predetermined sample volume determined in step 7.2 to the filter, using a graduated cylinder.

- Continue applying vacuum to remove all traces of water after the sample has passed through.

- While maintaining suction, wash the graduated cylinder, filter, non-filterable residue, and the walls of the filter funnel with three portions of distilled water, ensuring complete drainage between each wash. Remove all traces of water by continuing to apply vacuum after the water has passed through.

- Carefully detach the filter from the filter support, or alternatively, remove the crucible and filter from the crucible adapter.

- Dry the filter for at least one hour at 103-105°C. Allow it to cool in a desiccator and then weigh it.

- Repeat the drying cycle until a constant weight is obtained (weight loss is less than 0.5 mg).

- Calculate the non-filterable residue.

Membrane & pore size used in different countries

|

Country |

Method |

Glass-fiber Membrane |

Pore Size |

|

USA |

SM 2540 D |

Pall A/B Type |

1 um |

|

EPA 160.2 |

Millipore AP-40 |

0.7 um |

|

|

Reeves Angel 934-AH (Whatman grade 934 AH) |

1.5 um |

||

|

Gelman type A/E (or Pall type A/E) |

1 um |

||

|

Taiwan |

NIEA W210.58A |

Whatman grade 934 AH |

1.5 um |

|

Pall type A/E |

1 um |

||

|

Millipore Type AP-40 |

0.7 um |

||

|

E-D Scientific Specialties grade 161 |

1.1 um |

In a research study published in Analytical Methods (2018), water samples were filtered using glass fiber membrane filters and cellulose ester membrane filters, which had an effective filter membrane pore size ranging from 0.4 to 3 µm. The results indicated that there were no significant differences in the total suspended solids obtained between the two types of filters.

When selecting a filter membrane, it is important to consider the physical properties of the water sample itself and the particle size present. It is recommended to choose a filter with a smaller pore size for clear water bodies with lower turbidity, while selecting a filter with a larger pore size for turbid water to avoid rapid fouling of the membrane.

References:

–40 CFR Part 133 — Secondary Treatment Regulation, US EPA

–CHAPTER 5. Technology-Based Effluent Limitations, NPDES Permit Writers’ Manual, 2010

-Metcalf and Eddy, Wastewater Engineering-treatment, disposal, and reuse. McGraw-Hill, Inc., 1991

-Method 160.2 – Residue, Non-Filterable (Gravimetric, Dried at 103-105°C), US EPA

-Reverse Osmosis, Chapter 8 – RO Membrane Fouling, 2019

– Total Suspended Solids Dried at 103-105ºC and Total Volatile Suspended Solids Dried at 500°C, SM 2540 D

–What is the difference between Turbidity and TSS? Westlab, 2018

–What filter size are you using for Total Suspended Solids analysis?, ResearchGate