What is tangential flow filtration (tff filtration)?

Tangential flow filtration (TFF filtration) is a vital technique in the field of bioprocessing and purification, allowing for the separation, concentration, and purification of biomolecules and particles in solution. This topic holds significant importance due to its wide-ranging applications in biopharmaceutical manufacturing, protein purification, and the removal of contaminants from biological samples. TFF enables the gentle and efficient processing of large volumes of solution while minimizing sample loss and preserving the integrity of sensitive molecules.

By discussing TFF filtration, we gain insights into its principles, methodologies, and advancements, which contribute to the production of high-quality biologics, the purification of biomolecules, and the advancement of biomedical research. Therefore, exploring the topic of tangential flow filtration is essential for scientists, researchers, and bioprocessing professionals seeking efficient and scalable purification techniques for biotechnology and biomedical applications.

Membrane Filtration Technology and Tangential Flow Filtration Principle

Comparison of Tangential Flow Filtration and Traditional Filtration

Tangential Flow Filtration Membrane Types

Diafiltration with Tangential Flow Filtration Systems

Tangential flow filtration applications

Appendix: Selecting filter membranes for TFF systems

Membrane Filtration Technology and Tangential Flow Filtration Principle

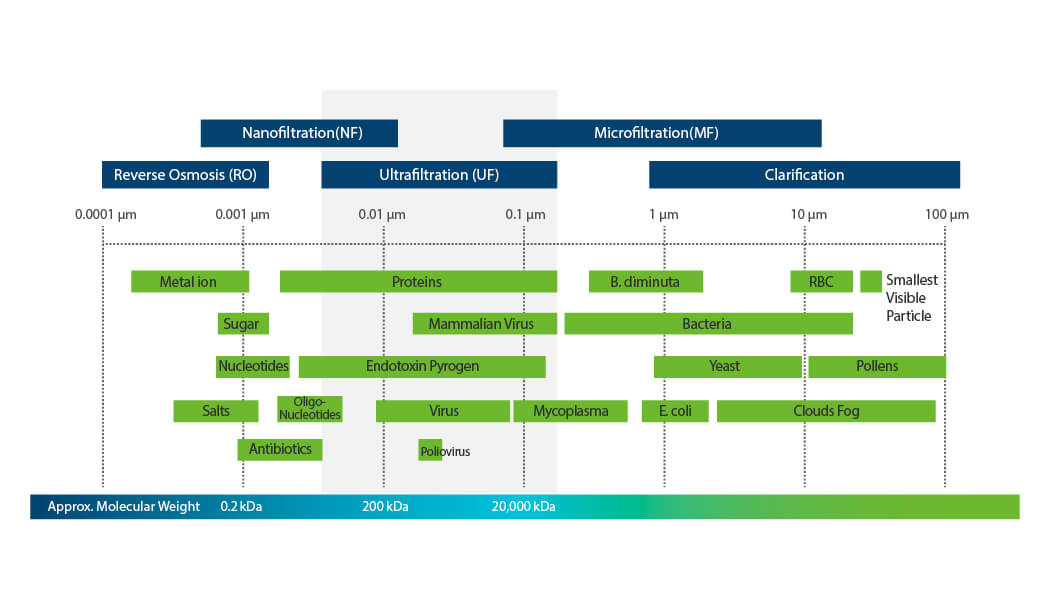

Membrane filtration is a widely employed technique for separation and purification, based on the size exclusion principle. It involves the use of various membrane filtration technologies, including reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF), microfiltration (MF), and clarification.

Among these technologies, microfiltration and ultrafiltration are the most commonly utilized in various industries. Microfiltration can effectively filter particles ranging from 0.1 to 10 micrometers, such as bacteria. On the other hand, ultrafiltration is primarily used for the separation of biomolecules in the size range of 0.001 to 0.1 micrometers, such as proteins and viruses. Ultrafiltration is considered relatively “gentle” as it causes minimal denaturation or inactivation of biomolecules during the treatment process. Therefore, it is advantageous for applications involving biomolecules.

Tangential Flow Filtration (TFF) is the prevailing technique used in ultrafiltration and is commonly employed in various biological fields, including molecular biology, biochemistry, immunology, protein chemistry, and microbiology.

Comparison of Tangential Flow Filtration and Normal Flow Filtration

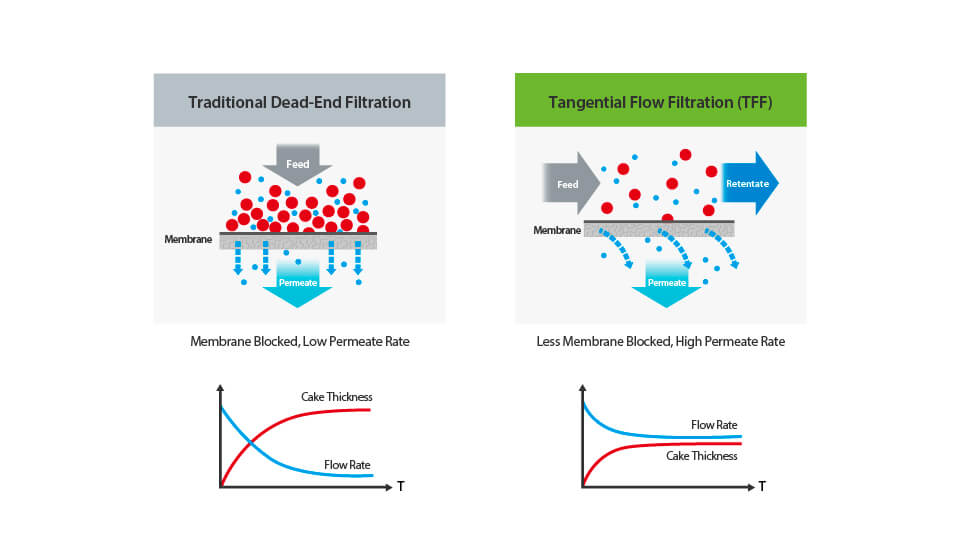

The traditional filtration method, known as direct flow filtration or dead-end filtration, involves the vertical flow of the sample through the membrane, allowing small molecules to pass through and be separated. However, this method has a drawback as macromolecules can accumulate on the membrane surface, forming a filter cake layer. As filtration time increases, the layer becomes thicker, leading to reduced filtration efficiency and a shorter lifespan for the membrane.

In contrast, tangential flow filtration operates with the sample flow moving horizontally across the membrane surface at a tangential angle. The sample flow is continuously filtered and rinses the membrane surface as it circulates, preventing the accumulation of macromolecules and reducing concentration polarization caused by reduced flow rates. This ensures a stable flow rate and effectively prolongs the lifespan of the filter membrane.

Tangential flow filtration offers additional advantages as it allows for both concentration and diafiltration simultaneously. Furthermore, the parameters used in experimental-level and production-level equipment are coherent, facilitating easy scale-up.

Due to these advantages, tangential flow filtration is increasingly preferred over traditional filtration in biotechnology and biomedicine-related fields, such as hospitals and the pharmaceutical industry.

ROCKER Tanfil 100 Tangential Flow Filtration System

◆ Plug & start all-in-one system

◆ Concentration and diafiltration at same run.

◆ Suitable for bioprocesses including DNA and RNA concentration

◆ Easy scale-up. Use same parameters for mass production.

◆ No more membrane fouling, longer lifespan.

◆ CE, RoHS, UKCA certificated

Lab scale tangential flow filtration (TFF) system – Tanfil 100

Tangential Flow Filtration Filter Membrane Types

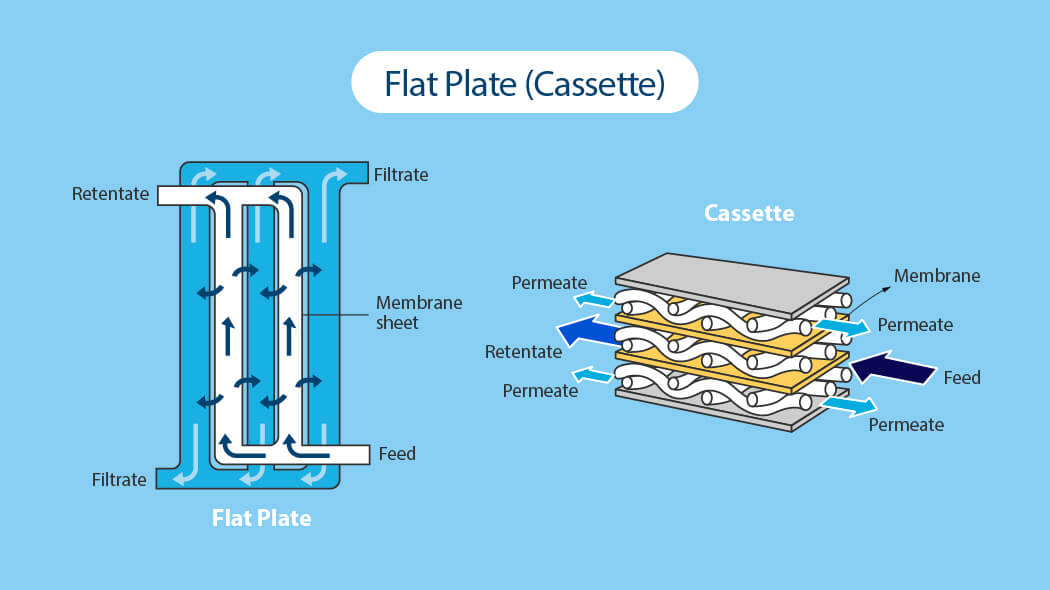

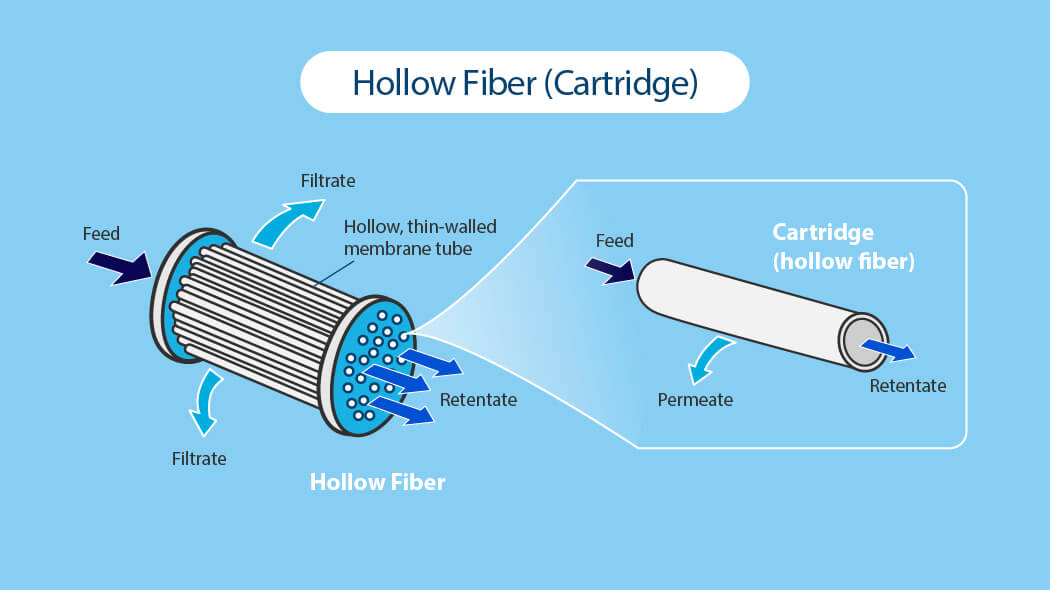

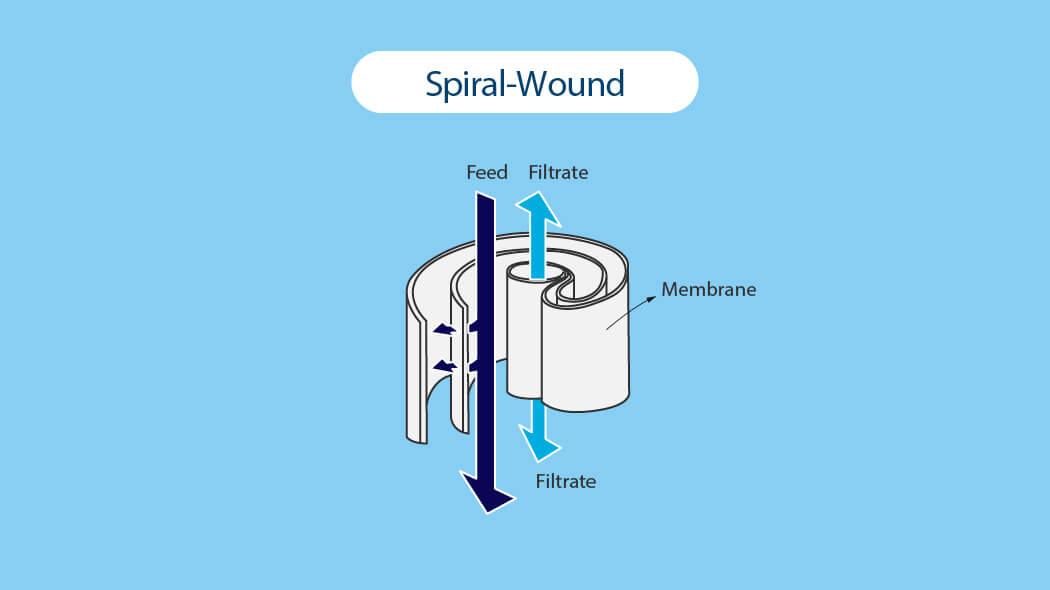

The Tangential Flow Filtration method can be applied using various types of tff filtration membrane modules, including flat plate (also known as cassette or capsule), hollow fiber, and spiral wound modules. Flat plate and hollow fiber membrane modules are preferred tangential flow filters in most laboratories.

|

Tangential Flow Filter(tff membrane) |

Flat Plate (cassette) |

Hollow Fiber |

Spiral Wound |

|

Volume ratio per surface area |

Low |

High |

Moderate |

|

Easy scale-up |

Yes |

Yes |

No |

|

Prevention of concentration polarization |

Yes |

No |

Yes |

|

Sample volume |

High |

Very high |

Low |

|

Recommended for |

• General biomolecules • Wastewater with high pollutants or high viscosity |

• Shear-sensitive substances, such as some enzyme and protein |

Samples that required large area to filter, such as food and beverage. |

|

Maintenance |

• Rinse with proper solvents |

• Rinse with proper solvents |

• Rinse with proper solvents |

Diafiltration with Tangential Flow Filtration Systems

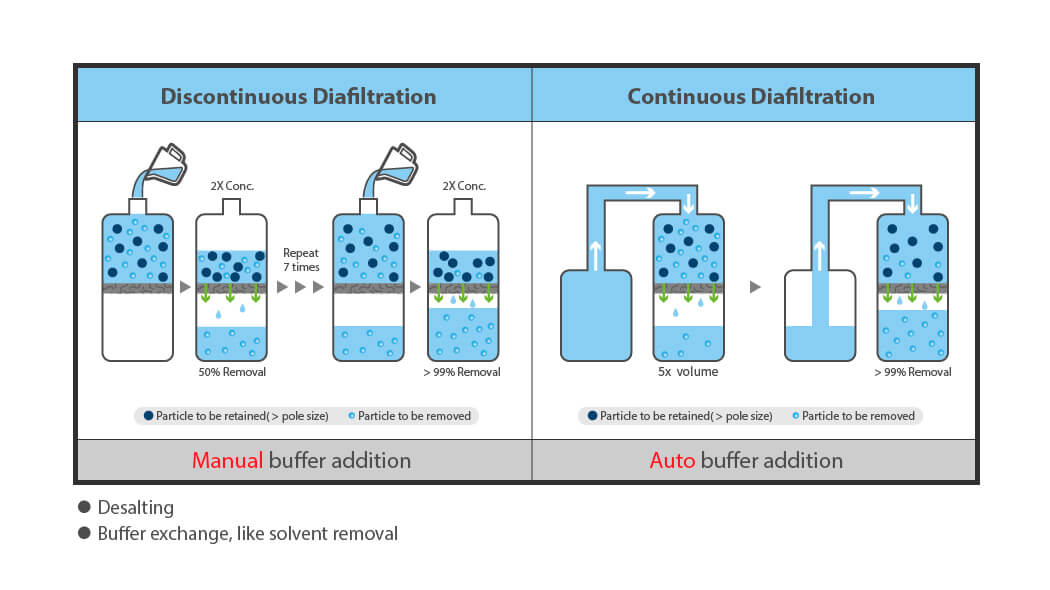

Diafiltration is a technique of ultrafiltration that involves the separation of small molecules, such as salt and protein, through membranes while simultaneously circulating macromolecules with fresh solvents. It is commonly employed for purposes such as salt removal or buffer exchange, similar to membrane dialysis. Diafiltration can be performed in either a continuous or discontinuous manner, depending on the specific requirements of the process.

Discontinuous diafiltration involves manually adding water or fresh buffer into the feed solution in fixed volumes, sequentially and repetitively, until the desired microsolute exchange is achieved. However, it is important to note that during the discontinuous diafiltration process, sample concentration may vary, and the permeate flow can gradually decrease as the concentration increases.

Continuous diafiltration, also known as constant volume diafiltration, is a method where the volume of the system is maintained at a constant level throughout the buffer exchange process. This is achieved by adding water or fresh buffer at the same rate as permeate generation. Continuous diafiltration is advantageous as it reduces the likelihood of biomolecule destruction or denaturation. Additionally, research has shown that continuous diafiltration can achieve 99% separation with less buffer usage compared to the discontinuous practice.

Taking desalting as an example, the concentration of salt can be reduced by adding diafiltration volume (DV). In a single filtration using continuous diafiltration, approximately 99% of the salt molecules can be removed by adding 5 DV. However, it would require 7 DV to achieve the same level of salt removal using the discontinuous filtration method.

In conclusion, continuous diafiltration is considered more advantageous and gentler in the treatment of biomolecules compared to discontinuous diafiltration. It offers greater efficiency in salt removal and is a preferred method for maintaining the integrity and quality of biomolecules during the purification process.

|

|

Discontinuous Diafiltration |

Continuous Diafiltration |

| Sample adding |

Manual |

Auto |

|

Required solvent volume |

More |

Less |

|

Sample recovery |

Lower |

Higher |

|

Preservation of biomolecule structure |

Worse |

Better |

|

Concentration in same system |

No |

Yes |

Applications of Tangential flow filtration system

- Concentration and desalting: proteins, peptides, nucleic acids (DNA, RNA)

- Separation and purification: enzymes, antibodies, recombinant proteins, viruses, vaccines, etc.

- Buffer exchange: solvent removal, dialysis, etc.

- Clarification: cell lysates, tissue homogenates, etc.

- Depyrogenation: such as water, buffer, culture medium, etc.

- Sample pretreatment that requires column chromatography.

- Cell collection

- Virus concentration, such as oncolytic measles virus

- Clinical: hemodialysis and hemoglobin purification

Appendix: Selecting filter membranes for TFF systems

TFF membrane structure designed for tangential flow filtration system is very different from that used in the direct flow filtration. Below given the points to consider before making decisions:

Keeping or removing the targeted molecule(s)

To keep: concentration

To remove: diafiltration, desalting, buffer exchange.

Size of target molecule(s)

There are two ways to define the size of a molecule when selecting tff membranes: by weight or by size. Molecular weight cut off (MWCO) and nominal molecular weight limit (NMWL) are both common units used to define molecular weight. Select membranes that are 1/6 to 1/3 smaller than the target molecule. µm is the unit used to define molecular sizes in diameter. When selecting membranes based on molecular size, make sure that the pore size is smaller than the target molecule. Please be reminded that molecular weight and size are not convertible to each other.

Desired recovery rate

The recovery rate is related to the MWCO (molecular weight cutoff). If a lower desired recovery rate is acceptable, a membrane with 1/3 of the MWCO of the target molecule may be sufficient and provide a quicker process. As the desired recovery rate increases, membranes with lower MWCOs down to 1/6 are suggested.Some materials, such as PES (polyethersulfone), may have a higher potential to bind to the sample and reduce the recovery rate. In cases that require a high recovery rate, cellulose-made membranes are recommended.

|

Consideration |

Description |

|

1. Target |

(1) Concentration → Keep (2) Diafiltration, desalting, buffer exchange → Remove |

|

2. tff membrane selection |

(1) Size of target molecule (MW) (2) Recovery rate |

|

Material – |

References:

-

- A review of polymeric membranes and processes for potable water reuse, Progress in Polymer Science, 2018

- Application of a Hollow-Fiber, Tangential-Flow Device for Sampling Suspended Bacteria and Particles from Natural Waters, 1990

- Diafiltration: A Fast, Efficient Method for Desalting, or Buffer Exchange of Biological Samples, Pall

- EVALUATION OF CLEANING SPIRAL WOUND MEMBRANE ELEMENTS WITH THE TWO-PHASE FLOW PROCESS, USBR, 2003

- Introduction to Tangential Flow Filtration for Laboratory and Process Development Applications, Pall

- Introduction to Tangential Flow Filtration (TFF), UGA Master of Biomanufacturing and Bioprocessing, University of Georgia

- Protein Concentration and Diafiltration by Tangential Flow Filtration, Millipore