What is vacuum filtration?

Vacuum filtration is a vital technique used in laboratories and industrial processes for the separation and filtration of solids from liquids through the application of reduced pressure. This topic holds significant importance due to its wide range of applications in various fields, including chemistry, biology, and environmental analysis. Vacuum filtration allows for efficient particle removal, clarification of solutions, and isolation of precipitates or solid residues.

How to set up vacuum filtration?

By discussing vacuum filtration, we gain insights into its principles, methodologies, and advancements, which contribute to improved sample purification, separation of mixtures, and removal of impurities. Exploring the topic of vacuum filtration is crucial for researchers, scientists, and technicians seeking reliable and efficient methods for liquid-solid separation and sample preparation in their respective fields.

Laboratory Filtration Methods

Vacuum Filtration Principle

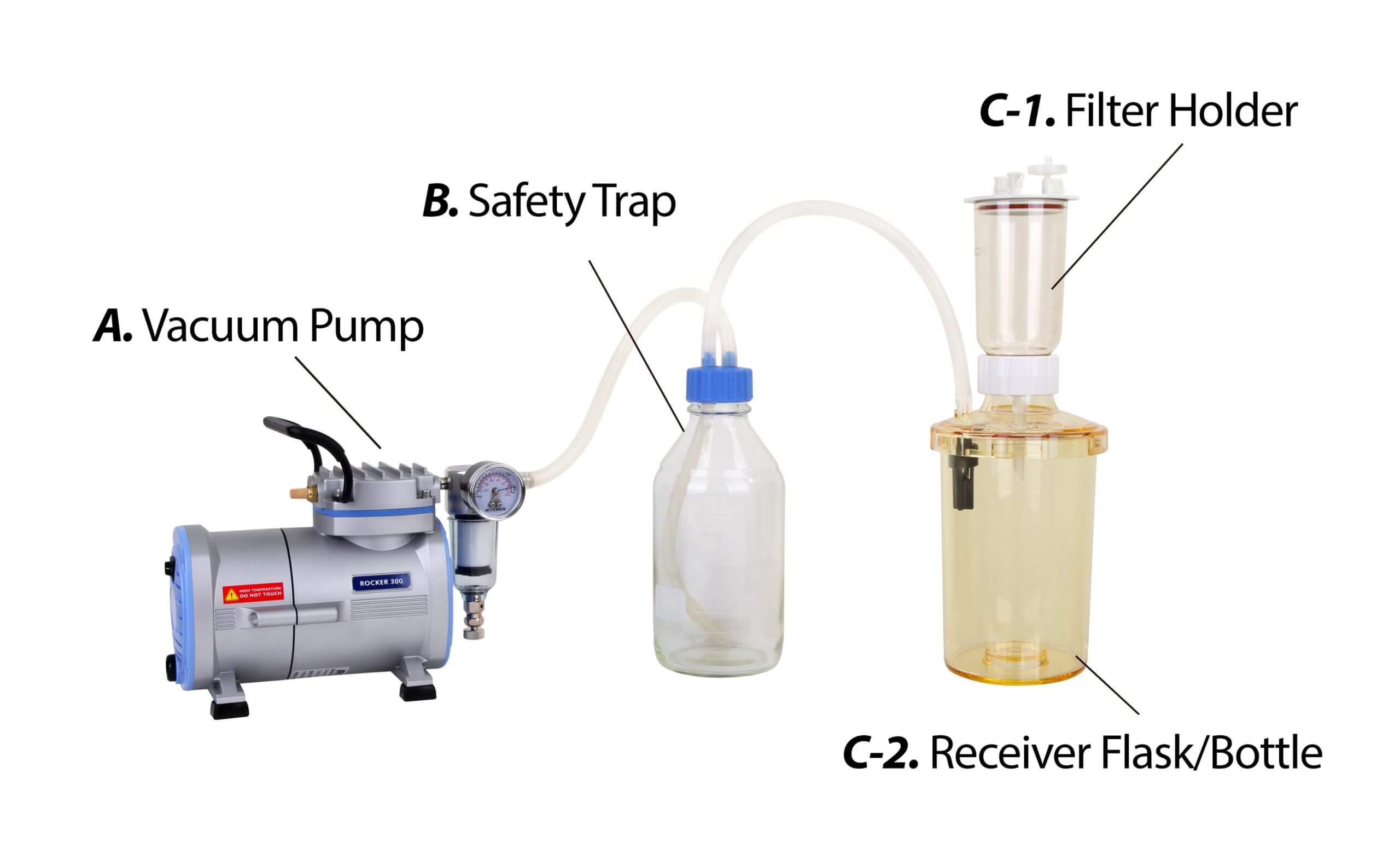

Vacuum Filtration Setup: Vacuum Pump, Safety Trap, Filter Holder, Receiver Bottle

Vacuum Filtration Applications

Laboratory Filtration Methods

Filtration aims to hinder suspended particles in a liquid using membrane filters or porous materials, thereby separating solid and liquid substances in a heterogeneous mixture to achieve separation and clarification. There are three commonly used laboratory filtration methods: gravity filtration, vacuum filtration, and pressure filtration. The appropriate filtration method should be selected based on the characteristics of the sample to be filtered, the desired efficiency in removing suspended particles, and the time required for filtration.

Vacuum Filtration Principles

Vacuum filtration, also referred to as negative pressure filtration, reduced pressure filtration, or suction filtration, involves creating a negative pressure in the container beneath the membrane. This negative pressure accelerates the liquid to pass through the membrane, resulting in the separation of solids from the liquid.

Vacuum Filtration Setup

Vacuum filtration setup often includes vacuum pump, safety trap, vacuum filtration apparatus(vacuum filter holder and receiver flask).

A. Vacuum Pump

The vacuum pump utilized in vacuum filtration is responsible for extracting gas molecules from a designated space, typically a laboratory flask or bottle, in order to achieve a desired pressure difference and facilitate the filtration process. In general, a pump with a vacuum of 685 mmHg is suitable for most filtration experiments, as this value represents a pressure difference of 90%. Only a small number of experiments may necessitate pumps with higher vacuum capabilities. (Note: 1 atmosphere is equivalent to 760 mmHg.)

How to select a proper lab vacuum pump?

-

-

Select the type of pump based on the nature of the sample, whether it is a general water solution, organic solvent, or corrosive substance. Watch and learn how to choose the right pump for your laboratory.

-

When selecting the appropriate vacuum, consider the characteristics of the sample, such as the presence of suspended particles and the viscosity of the liquid. Generally, samples with higher viscosity or more impurities require a higher vacuum level to achieve satisfactory results. If you encounter difficulties with vacuum conversion, learn how to perform correct vacuum conversion to ensure accurate measurements.

-

Choose a suitable pump flow capacity based on the volume of the filter bottle. The larger the filter bottle, the higher the required flow rate should be.

-

Reasons to choose Rocker Oil-free Vacuum Pumps rather than general water pumps:

- Stable vacuum degree and decompression efficiency under different temperature.

- More environmental friendly for not needing additional water.

- Create no water pollution.

Rocker 300 Vacuum Pump fits most laboratory experiments with Max. vacuum at 685 mmHg.

Rocker 300 oil free vacuum pump – laboratory vacuum pump for filtration

Read more: Chart – Rocker Laboratory Filtration Pumps (Appendix I)

B. Safety Trap

A safety trap is typically installed between the pump and the receiver bottle in a vacuum filtration system. Its purpose is to prevent the filtrate from flowing back into the pump as a result of improper operation, which could potentially damage the pump. In a laboratory filtration system, a safety trap can be a GL45 glass storage bottle, a vacuum bottle, or a waste bottle.

How do you protect pumps from liquid damage? Prote™ Filter Cartridge (YouTube video link)

C. Vacuum Filter Holder(vacuum filtration apparatus)

Filter holders are used to secure filter membranes and facilitate the passage of liquid through the membrane during filtration. They can be attached to the top of receiver bottles using either silicone stoppers or a spin lock mechanism.

D. Receiver Flask(vacuum filtration apparatus)

Receiver flasks, also referred to as suction flasks or waste flasks, serve as the containers that are connected to the vacuum pump to collect the filtrate during the filtration process. These flasks are sometimes connected to a safety trap using silicone tubes

How to select proper vacuum filtration apparatus (filter holders and receiver flasks)?

- Filter holders are to be chosen based on the volume of sample. Common size of filter holder includes 25 mm, 47 mm and 90 mm (in diameter). The larger the volume of sample, the larger size holder is suggested.

- Material of filter holder and receiver flasks should be selected according to chemical characteristics of sample solvent(s). For more information, please refer to chemical compatibility chart.

Read more: Rocker Vacuum Filter Holders (Appendix 3)

Vacuum Filtration Application(s)

- Aqueous solution filtration, such as suspended solids, microorganisms, etc.

- Clarification of cell culture media and buffers.

- Separation of chemical synthesis.

- Roughing filtration of industrial solvent.

Literature references

| Literature | Author | Method applied |

| Cryopreservation of the gorgonian endosymbiont Symbiodinium | Gabriella Chong et al. | Seawater filtration (filtered seawater (FSW) preparation) |

| First instance of settlement by cryopreserved coral larvae in symbiotic association with dinoflagellates | Luca Cirino et al. | Seawater filtration (filtered seawater (FSW) preparation) |

| Detection and characterization of small-sized microplastics (≥ 5 µm) in milk products | Paulo A. Da Costa Filho et al. | Milk sample filtration |

| Solvent polarity mediates phytochemical yield and antioxidant capacity of Isatis tinctoria | Abdul Wakeel et al. | Vacuum drying |

Appendix 1: Rocker Oil-free Vacuum Pump

All Rocker’ vacuuming pumps are oil-mist-free and maintenance-free.

|

|

For air |

For liquid |

||

|

Series |

||||

| Type |

Oil-free |

|||

|

Drive |

Piston |

Diaphragm |

||

|

Proper for Sample |

Non-chemical |

Organic solvent |

Organic or corrosive solvent |

Non-chemical |

|

Feature |

• Prote™ Filter Cartridge |

• PTFE-coated, suitable for most chemicals. |

• PTFE-made. High chemical resistance. |

• Draws both air and liquid, direct drainage. |

Appendix 2: Rocker Vacuum Filtration System Applications

|

Applications |

Vacuum filtration |

Solvent purification |

Microbiological filtration |

Suspended solids filtration |

|

ROCKER vacuum filtration system

|

|

|

|

|

|

|

|

|

|

|

Appendix 3: Rocker Vacuum Filtration apparatus (filter holder)

|

|

MF Series | LF Series | SF Series | VF Series | |

|

|

|

|

|

|

|

|

Connection Method |

Magnetic coupling |

Spin-lock design |

Spin-lock design |

Clamp |

|

|

Filter Membrane Diameter |

47 mm |

47 mm |

47 mm |

25 / 47 / 90 mm |

|

|

Filter Holder Material |

PPSU |

PES |

PES |

SS316 Stainless Steel |

Borosilicate glass |

|

Autoclave |

V |

V |

V |

V |

V |

|

Features |

• one-hand operation • Compatible with various kinds of vacuum bottles |

• Clamp-free spin-lock design

|

• Rapid flame sterilization |

• Quick and easy disconnection with screwthread connector at side arm |

|

|

Applications |

• vacuum filtration • total suspended solids in water • Continuous vacuum filtration |

• vacuum filtration • total suspended solids in water |

• microbial testing • total suspended solids in water |

• HPLC mobile phase preparation • Organic solvent filtration |

|

Reference: